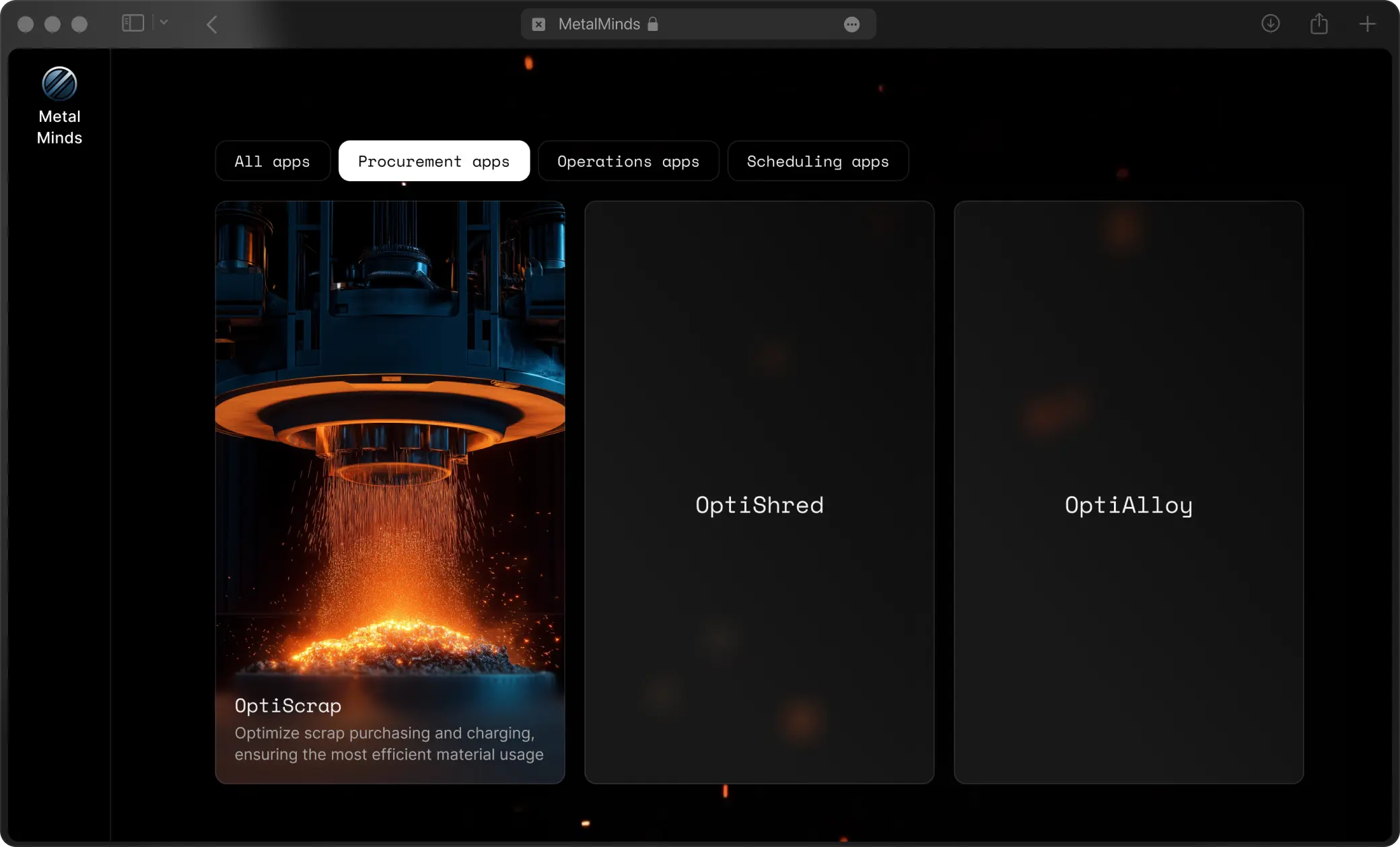

The AI-powered decision platform for Steelmakers

Meet the platform that helps you make faster, smarter, cost-saving decisions across the entire value chain

Metal Minds analyzes your operations and helps take them to the next level — from scrap and alloy decisions to full-scale production planning

Over $50

achieve savings per steel MT1

1 – estimated savings with full-scale deployment of the entire Metal Minds solution portfolio are $22-57 per MT

Up to $26/MT

Procurement

Up to $11/MT

Operations

Up to $20/MT

Planning

Foundational solutions

Procurement apps

Operations apps

Scheduling apps

On-site diagnostics

We go on-site, talk to your team, observe how things work, and dive deep into your operations

Custom configuration

Based on diagnostics, we configure the solution to fit your specific workflows

Integration

We work with your team through implementation, training, and daily usage to ensure the tools are embedded in operations

Support and refinement

After launch, we monitor performance, recalibrate if needed, and continuously improve the solution with your input.

Ready to optimize your operations?

Request a demo — and see how we can improve scrap purchasing, melt planning, and production efficiency in your first month.

Need more details?

Most customers start seeing measurable results within the first 1–3 months after roll-out. Depending on specifics and customization requirements this timeline will be updated.

No additional hardware is required. Our AI platform integrates seamlessly with your existing production environment and focuses on optimizing your current equipment and processes. Some specific use cases (computer vision) would require camera upgrade and/or installation of LiDAR systems for full capabilities.

Our solutions are designed for smooth integration with plant control systems, ERP, and MES platforms. A typical implementation takes a few weeks to a few months, depending on the complexity of your operations and chosen solution set.

Not at all. Our user interfaces are built to be intuitive and require minimal training. We provide onboarding workshops, but the goal is for your operators and engineers to focus on decision-making, while our AI handles the heavy calculations in the background.

Yes. After initial deployment, your IT team can handle standard system administration. We provide ongoing remote monitoring, updates, and recalibration to ensure peak performance and adapt the models to changing conditions.

We do offer a limited-time custom trial, that would not yet be tailored to your plant’s unique processes and data. However, it enables you to test the models on a smaller scale before full rollout.

Both options are available. Many clients start with a specific module (e.g., OptiScrap or SmartPlan) and expand over time. Others choose the full solution portfolio for maximum value. We tailor the approach to your priorities and budget.